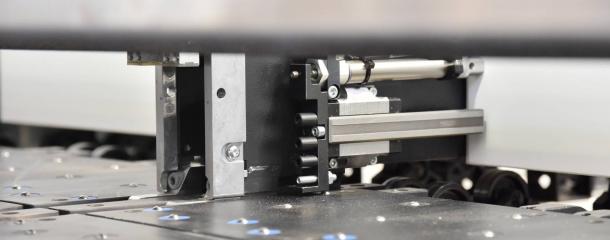

Guide to beamsaws | 7... also?For processing panels with protruding top layers, such as e.g. veneer or lamination, trimming stops for veneer has to be installed on collet chucks, which are flapped or shoved to the front if a defined measure is required, in order to prevent damages of the protruding top layers by collet chucks. Processors of kitchen worktops and panel materials with soft and postforming edges frequently order a saw with a postforming-prescoring-unit. As opposed to the standard pre-scoring units, which cuts a ca. 2 mm deep groove into the panel bottomg side and thus just cuts the surface, the postforming pre-scoring unit shortly ascents in the edge area of the workpeice and cuts through the workpiece edge completely. Thus one ensures the soft and postforming edges not to be damaged through the counter-rotating main sawblade when carrying out the main cut. In order to be able to work with a panel sizing saw similarly flexible to a sliding table saw, manufacturers come up with some ideas. Thus concepts for angular cuts are available and such for mitre cuts. Latter option faciliates e.g. Homag with the »Module 45« installed on the angular ruler. Another solution comes from Panhans/Schelling with the »S 45« with sawblade pivoting. For the sake of completion, one should mention that automatic labelling stations on panel saws exist which apply the labels already onto the raw plate before cutting. In the manual field, label printers are common besides the control panel. The printed label is made available for the unloading process to the machine operator in compliance with the advancement of cutting technology. |

CNC machining centres, robots894

Edgebanding, edge processing627

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology199

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131