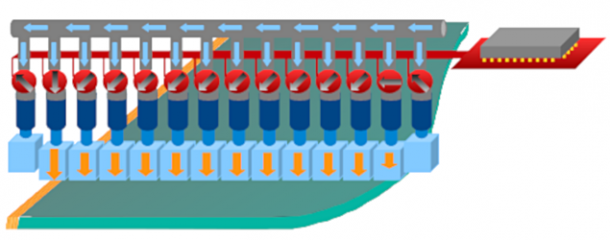

Guide to wide belt sanders | 6Electronically controlled segment grinding shoelongitudinal sanding pad aggregates and combined sanding roller-sanding pad aggregates can be equipped with a segmented pressure beam with electronic control. Sensing rollers or laser cameras detect the geometry and the surface of the workpieces. The control system calculates the pressure that the individual segments exert on the grinding belt. The operator determines how special zones are handled. For example, higher pressure is applied at the edge of the workpiece if it is a veneered panel with solid wood lipping. The pressure is reduced if the lacquer layer in the edge area is not to be sanded through. The segmental pressure pad can be used to precisely calibrate the lacquer build-up in the edge area. This is particularly necessary for irregularly shaped workpieces in the high-end sector. Some machine controls offer frame sanding programs. The machine takes the grain pattern into account of the individual frame parts by switching on the segments of the cross sanding- and lengthwise sanding aggregate accordingly. The pressure of the individual segments can be carried out electropneumatically or electromagnetically. Pressure beams with pneumatically moved segments are usually cheaper to purchase. Magnetically moved segments are said to be more reliable. |

CNC machining centres, robots896

Edgebanding, edge processing624

Saws, cutting machines437

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers180

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines321

Mechanisation, storage, packing technology198

Surface coating151

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131