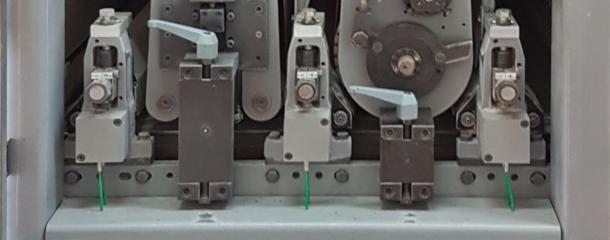

Floating pressure rollersFloating pressure rollers ("swimming rollers") support the workpiece guidance in wide belt sanders by pressing the workpiece from above onto the feed belt. These pressure rollers are arranged between the aggregates. The distance between these pressure rollers is decisive for the minimum workpiece length. They prevent short workpieces from standing up between the sanding units and ensure that thin workpieces do not flutter. In order to ensure a full-surface pressure, the rolls are fixed on both sides. If the thickness of the workpiece should drop slightly to one side, this is compensated for by this type of fixture. Grooved pressure rollers compensate for differences in thickness of workpieces that pass through the machine side by side. The pressure of the rollers is usually applied by spring force. Machines with floating feed tableOn machines with a floating feed table, the pressure rollers can be adjusted differently depending on the sanding task.

|

CNC machining centres, robots894

Edgebanding, edge processing622

Saws, cutting machines436

Planers, 4-sided moulders190

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines324

Mechanisation, storage, packing technology197

Surface coating149

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum139

Assembly, worktables15

Lathes29

Tools, sharpening technology99

Equipment, Other machines124