Paul Ernst Maschinenfabrik GmbH

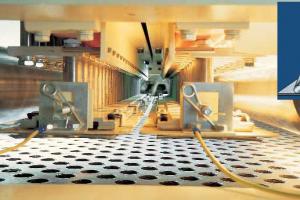

Manufacturer of wide-belt sanders and deburring machines, based in Eschelbronn/ Germany. Since 1 January 2015, the company Ernst is part of the Wintersteiger association/ Austria.

History

| 2015 | The Paul Ernst machinery company is taken over by the Wintersteiger group. |

| 2014 | Standard machines for woodworking are no longer offered. |

| 2010 | Paul Ernst GmbH is one of the technology leaders in the field of plate deburring machines and sanding machines for lacquer and wood (doors and furniture industry). It is a medium-sized German, owner-managed company. The export share amounts to 70%. |

| 2008 | June: Acquisition of the shares and the management by Martin Freudenberg and Markus Lindörfer. |

| 2007 | Delivery of a complete grinding line (top and bottom) to Case New in Fargo, USA. |

| 2004 | Development of a machine releasing oxide from laser sections (up to a thickness of 25 mm) at the front sides. |

| 2003 | Delivery of a high-performance grinding machine for veneer sanding with feed speeds up to 50m feed per minute. |

| 2002 | Establishment of the sales subsidiary ERNST-Schweiz GmbH. |

| 2000 | Development of a machine with an automatic tool changer, that incorporates one set of abrasive flaps - brushes for extreme edge rounding. Moreover, there is an additional pair of wire scratch brushes of stainless steel that enables (normal) edge smoothing and oxide-removal from the strips. |

| 1999 | Development of the plate deburring machines to a modular construction kit (which makes it possible to respond to specific requirements from the customers), inclusion of the wide-belt unit in the programme. |

| 1998 | First grinding machine worldwide with a touch-screen interface, that can be used intuitively (only the type of wood and paint has to be entered). |

| 1993 | Development of the Duplex-System: Two independently switched, electronically controlled pressure beams work in a wide-belt unit; receipt of the Innovation Award of Baden-Wuerttemberg (honoured for examplary innovative, entrepreneurial achievements in the development of new products and processes and for the application of modern technology in the production). |

| 1989 | Electronic passage measurement and setting system MES. |

| 1983 | Tele-diagnosis system for remote access to grinding machines. |

| 1981 | Electronically controlled lacquer sanding machine with continous adjustment of the cutting speed. |

| 1980 | Energy saving system for grinding machines, development of a device for fault detection. |

| 1979 | Development of a wide-belt unit with electronic individual control of the pressure elements, construction of the first machine for grinding irregularly shaped parts. |

| 1978 | Presentation of the first floating beam components. |

| 1977 | Several developments: construction of the roller pressure beam (no more sliding friction), beam with 35/40 mm link spacing, development of the segment belt drive and a grinding belt slideway on three rolls (to avoid tearing of the grinding belt). |

| 1968 | Introduction of the cross-sanding mode: a cross-grinding longitudinal belt performs the pre-grinding, the following wide belt unit(s) do the polish. |

| 1963 | Construction of the 100th buffing machine. |

| 1962 | Production start of grinding machines: breakthrough with an intermediate lacquer sanding machine that was used in coating lines and sold over 2,500 times. |

| 1960 | Development of a buffing machine for polishing polyester-painted surfaces, due to the high demand from the local furniture industry. |

show full history