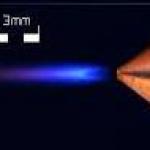

Zero joint - hydrogen technologyIt is possible to create a zero joint through using direct combustion heat. Hydrogen technology uses the heat generated during the combustion of hydrogen and oxygen to activate the functional layer of of the zero joint edge band. Only 10 % of the energy required for hot air technology is consumed in this process. Mode of operationThe flames of the hydrogen-oxygen mixture are directed towards the edge band with the aid of a row nozzles. The heat of combustion melts the functional layer. The subsequent pressure roller presses the edgeband against the narrow surface of the workpiece so that the plastic melt of the functional layer penetrates into the pores of the workpiece. Cooling the plastic melt through a full-surface joint between the workpiece and the edgeband. ProviderThe company HyFuse Limited from New Zealand received the patent for hydrogen technology in 2018 in several states. In New Zealand and Australia HPTech is building the HyFuse-unit onto existing edgebanders. There is an agreement with a European machine manufacturer that only machines older than two years may be retrofitted. Biesse describes in its annual report 2019 the content of the Hyfuse project as an innovative edge application system based on the energetic activation of the adhesive layer and concludes: "The patented system completes the range of solutions offered by Biesse in this field". |

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131