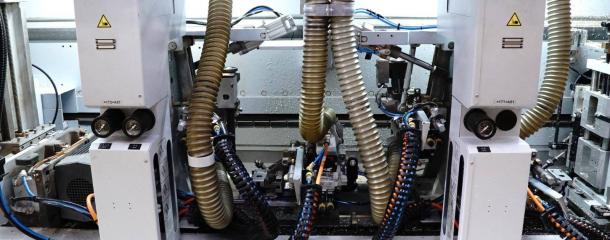

HOMAG FF 30Corner rounding unitDesignation for a contour milling aggregate of the manufacturer HOMAG, used on edge banding and processing lines for milling the leading and trailing edge of the workpiece with 4 milling motors. The aggregate enables the manual quick change of tools due to a special tool interface. In contrast to the units Homag FK 11 and FK 13, the FF 30 unit has 4 milling motors. As each motor is used for machining one of the four edge corners, milling can be done in down-cut, which enables the machining of veneer edges. Technical data

Options:

|  HOMAG FF 30 HOMAG FF 30

| |||||

CNC machining centres, robots895

Edgebanding, edge processing625

Saws, cutting machines439

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines321

Mechanisation, storage, packing technology197

Surface coating152

Production lines126

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum141

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131