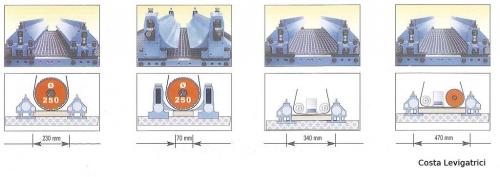

Pressure pads for short workpiecesThey consist of rubber rollers in a heavy support structure, and are preferably made of cast iron. They have the task of providing a safe workpiece through-feed through the machine. The workpiece must be pressed so heavily on the feed conveyor that it can not slip or bulge out. At the same time, the pressure pad has to be able to adapt to the varying thickness of the workpiece during calibrating. This is achieved by pneumatic suspension of the support structure. Versions

|

CNC machining centres, robots894

Edgebanding, edge processing622

Saws, cutting machines436

Planers, 4-sided moulders190

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines324

Mechanisation, storage, packing technology197

Surface coating149

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum139

Assembly, worktables15

Lathes29

Tools, sharpening technology99

Equipment, Other machines124