User interface, machine control, optimization computer

- Used in the 1990s until the mid-2000s

- According to the manufacturer, it can be operated without computer skills

- Storage capacity for 300 different lengths, divided into 10 cut lists

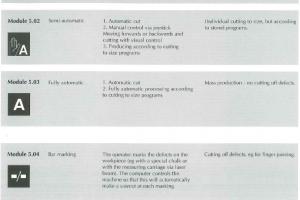

Depending on the application, different control modules are used:

- Module 5.01

- Length cutting and manual error trimming

- Module 5.02

- Semi-automatic - length cutting based on cutting lists

- Module 5.03

- Fully automated for mass production, without error detection

- Module 5.04

- Especially for error trimming; labeling by chalk marking or laser guide light

- Module 5.05

- Partial optimization; Error trimming similar to Module 5.04, but with determination of the maximum fixed length according to the parts list

- Module 5.06

- Full optimization based on priorities set (length, quantity, assessment ratio, minimum wastage, ..)

- Module 5.061

- Similar to Module 5.06, but with consideration of quality (quality optimization)

- Module 5.062

- Similar to Module 5.06, but with regard to the width of workpiece

- Module 5.07

- Full optimization with consideration of values for each workpiece, consideration of timber quality

Further development: Control 6.0