HOLZ-HER 1907 ultra-granupressGlue systemGlue application station 1907This glue application unit combines the advantages of the glue system cartridge with the high availability of adhesive granules. Design and mode of operationA large stainless steel hopper serves as a reservoir for the hot melt glue pellets. At the lower end of the hopper, granulate can be dropped from the hopper into a rectangular cylinder by a pneumatic slide. Under high pressure, a piston forms a rectangular glue cartridge from the granules. The side of the cylinder opposite facing the piston is heated and perforated many times. There, the glue cartridge is melted at its front. Liquid glue passes through the heated channels and is applied to the workpiece edge by a glue nozzle using a transportation device. Technical data

Advantages

Availability

Usable adhesives

Alternative and similar terms

|

| |||||||

Images

Product brochures and leaflets (1)

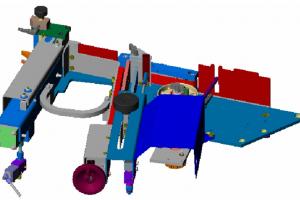

Aggregates

source: Höchsmann GmbH

©

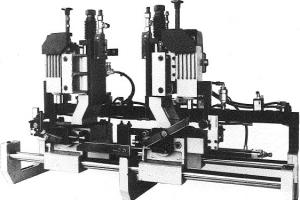

Fine milling unit

source: Höchsmann GmbH

©

Trimming saw

source: Höchsmann GmbH

©

Corner rounding unit

source: Höchsmann GmbH

©

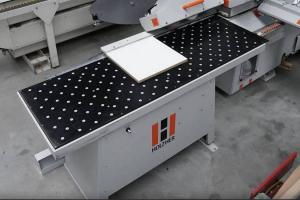

Glue system

source: Höchsmann GmbH

©

Profile scraper unit

source: Höchsmann GmbH

©

Workpiece infeed

source: HOLZ-HER

©

Special aggregate

source: Höchsmann GmbH

©

Flat scraper unit

source: Höchsmann GmbH

©

Spraying device

source: HOLZ-HER

©

Guidance for short lengths