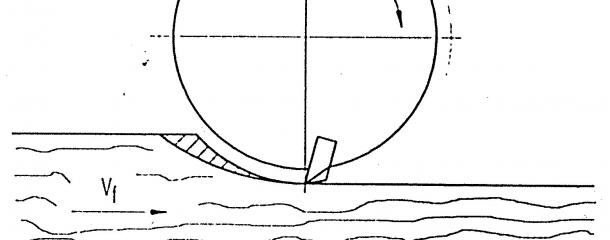

Rotation against feed directionDirection of rotation of a rotatable, cylindrical machine part (e.g. cutter block, feed roller, glue roller, metering roller, application roller, ...) in relation to the workpiece or another machine part. Here, 'up-cut' means that the movements of the parts do not lead to a common feed direction. Milling tools, planer headsThe cutting movement of the tool is opposed to the feed movement of the workpiece. The cutting of the wood does not start with the blade hitting the workpiece, but only at the beginning of the upward movement of the blade. Before, the blade's edge scrapes and pushes. During the upward movement, the cutting process begins. The resulting chips are elongated and their thickness increases. Advantages

Disadvantages

ApplicationDue to its economic advantages in terms of tool life, the majority of cutting operations on woodworking machines are carried out in up-cutting. In order to nevertheless achieve a good cutting quality and to exclude chipping, down-cut spindles are used. Sanding aggregatesSanding aggregates also usually work in up-cut, as this ensures a high chip removal and a short dwell time of the abrasive on a certain workpiece surface (keyword heating). |

CNC machining centres, robots896

Edgebanding, edge processing628

Saws, cutting machines437

Planers, 4-sided moulders187

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines321

Mechanisation, storage, packing technology201

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131