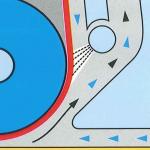

AbblaseinrichtungMit Druckluft arbeitende Reinigungsvorrichtung für Schleifband, Werkstück und Vorschubteppich. Sie kann mit Luft aus dem Druckluftnetz oder aus einem eigenen Ventilator gespeist werden. Die Reduzierung des Druckluftverbrauchs ist z.B. durch Einsatzsteuerung möglich, d.h. die Düsen arbeiten nur, solange das Werkstück durch das zugehörige Aggregat bearbeitet wird. SchleifbandreinigungDie Bandreinigung in Breitbandschleifmaschinen wird mit Hilfe von Druckluft aus oszillierenden Düsen durchgeführt. Besonders effektiv sind dabei unmittelbar an der Umlenkrolle in einem Absaugkanal sitzende Blasdüsen. Durch das Wölben um die Umlenkrolle vergrößern sich die Zwischenräume zwischen den Schleifkörnern, so dass der darin haftende Staub ausgeblasen werden kann. Die Schleifbandreinigung sorgt für ein gleichmäßig 'feines' Schleifbild und erhöht die Standzeit des Schleifbandes. Alternative Bezeichnungen einiger Hersteller:

WerkstückreinigungDie Notwendigkeit zur maschinellen Werkstückreinigung besteht vor allem bei Breitbandschleifmaschinen in Lackierstraßen. Die Werkstücke müssen vor dem Lackauftrag absolut staubfrei sein, werden aber nach dem Schleifen nicht noch einmal von Personal in die Hand genommen. Wird die Reinigung nicht durch spezielle Bürstmaschinen realisiert muss die Breitbandschleifmaschine mit entsprechenden Werkstückreinigungseinrichtungen ausgerüstet sein. Die Abblaseinrichtung besteht hier meist in rotierenden Düsen. Zusätzlich kommen Reinigungsbürsten (Bürstaggregat) und Ionisiereinrichtungen zum Einsatz. Einige Maschinenhersteller integrieren auch WANDRES Reinigungsaggregate in ihre Maschinen. Alternative Bezeichnungen einiger Hersteller:

|

CNC-Stationärmaschinen, Roboter893

Kantenanleimen, Kantenbearbeitung630

Sägen, Schneidemaschinen438

Hobelmaschinen, Kehlmaschinen188

Fräsmaschinen, Zapfenschneider181

Bohrmaschinen, Stemmmaschinen135

Pressen, Zusammensetzmaschinen201

Schleifmaschinen321

Mechanisierung, Lagern, Verpacken200

Oberflächenbeschichtung152

Fertigungslinien127

Heizen, Trocknen, Zerkleinern62

Absaugung, Druckluft, Vakuum134

Montagetechnik, Arbeitstische15

Drechsel- und Drehmaschinen29

Werkzeuge, Schärftechnik91

Zubehör, Sonstiges131