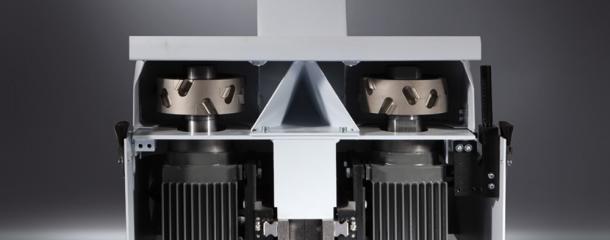

FügefräsaggregatAggregat in Kantenanleimmaschinen zum ausrissfreien Planfräsen der Werkstückkanten vor dem Kantenanleimen. AnwendungHolzwerkstoffplatten für den Möbelbau sind besonders im Kantenbereich empfindlich. Lagerung bei erhöhter Luftfeuchtigkeit (Witterungswechsel) lässt die Werkstück-Randbereiche quellen. Beim Aufteilen auf Formatkreissägen bzw. vertikalen Plattensägen ohne Vorritzaggregat, entstehen Ausrisse auf der Werkstückoberfläche. Falsch eingestellte Vorritzer auf Plattenaufteilsägen können zu konischen Schnittkanten führen. Auch Beschädigungen während des innerbetrieblichen Transports sind möglich. Um diese vor dem Anleimen der Kante zu beseitigen, werden Fügefräsaggregate eingesetzt. Da das Fügefräsen unmittelbar vor dem Anleimen der Kante geschieht werden auch kleine Maschinen zunehmend mit Fügefräsaggregaten ausgestattet. In der Regel bestehen Fügefräsaggregate aus 2 zueinander (gegenläufigen) Frässpindeln, welche vorzugsweise mit Diamant-Fräswerkzeugen bestückt sind. Die erste Spindel ist dem Werkstück gegenüber gegenläufig. Diese Spindel fräst nur ein kleines Stück der Werkstückkante und taucht danach aus, um ein Ausreißen am Ende der Werkstückkante zu vermeiden. Die zweite Spindel ist zum Werkstück gleichläufig und fräst die Kante bis zum Ende plan. Die Spanabnahme beim Fügefräsen beträgt ca. 1 mm Alternativbegriffe

|

CNC-Stationärmaschinen, Roboter894

Kantenanleimen, Kantenbearbeitung627

Sägen, Schneidemaschinen436

Hobelmaschinen, Kehlmaschinen186

Fräsmaschinen, Zapfenschneider181

Bohrmaschinen, Stemmmaschinen134

Pressen, Zusammensetzmaschinen201

Schleifmaschinen320

Mechanisierung, Lagern, Verpacken199

Oberflächenbeschichtung152

Fertigungslinien127

Heizen, Trocknen, Zerkleinern63

Absaugung, Druckluft, Vakuum140

Montagetechnik, Arbeitstische15

Drechsel- und Drehmaschinen29

Werkzeuge, Schärftechnik91

Zubehör, Sonstiges131