Optimalizace při kapovacím řezání

Záznam uvidíte za

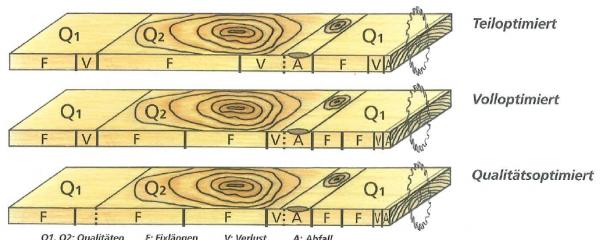

The types of optimization in the field of solid wood cross cut saws are not standardizes and won't be described consistently. The manufacturers use different phrases and make their machines fit individual customer requirements. Following terms are to be noted:

alternative words:

|

CNC obrábění883

Opracování hran616

Pílení438

Hoblování186

Frézování181

Vrtání, Dlabání132

Lisování, Spájení202

Broušení325

Dopravníky, Skladování, Balení188

Povrchová úprava149

Výrobní linky124

Topení, Sušení, Drcení61

Odsávání, Stlačený vzduch, Vakuum130

Technika montáže, pracovní stoly11

Soustružení34

Nástroje, Ostřeší96

Ostatní, Příslušenství96