LED technology

You see the entry in

LED - Light Emitting Diodes

Purpose 1: visible light

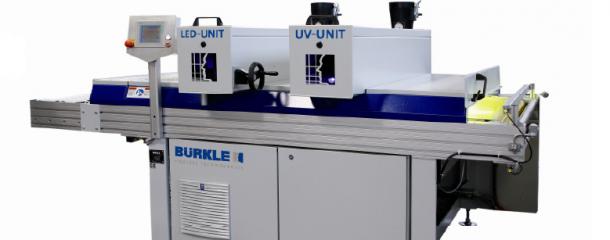

Purpose 2: UV radiation - Tempering of coatingsThe first concepts for the use of LED technology in the surface coating of wood were developed by the company Bürkle in 2008. Meanwhile, many manufacturers that are active in the area of surface finishing offer UV-LED-systems. Hybrid-Versionen'Hybrid version' means a combination of LED radiation sources and conventional mercury and gallium lamps. Essential advantages of the LED technology in the area of wooden surfaces in comparison with conventional UV technology with for example mercury and gallium lamps:

It is obvious that manufacturers put much effort into the reduction of current limitations of application concerning the LED technology and thus try to enable new usage areas. However, the two areas adhesive processing and digital print are regarded as established. It is assumed that further application areas will follow, where the UV-LEDs can completely unfold their specific advantages (nearly monochromatic, low reactions timelow temperature). |

CNC stacionarne mašine, roboti891

Kantovanje, obrada ivica619

Testere, mašine za rezanje433

Rendisaljke, glodalice186

Glodalice, tenon rezači179

Mašine za bušenje, glodalice133

Prese, mašine za montažu203

Mašine za brušenje323

Mehanizacija, skladištenje, pakovanje194

Površinski premaz152

Proizvodne linije123

Grijanje, sušenje, sjeckanje62

Usisavanje, komprimirani zrak, vakuum136

Tehnologija montaže, radni stolovi13

Strugovi i stružnice30

Alati, tehnologija oštrenja97

Dodatna oprema, ostalo109