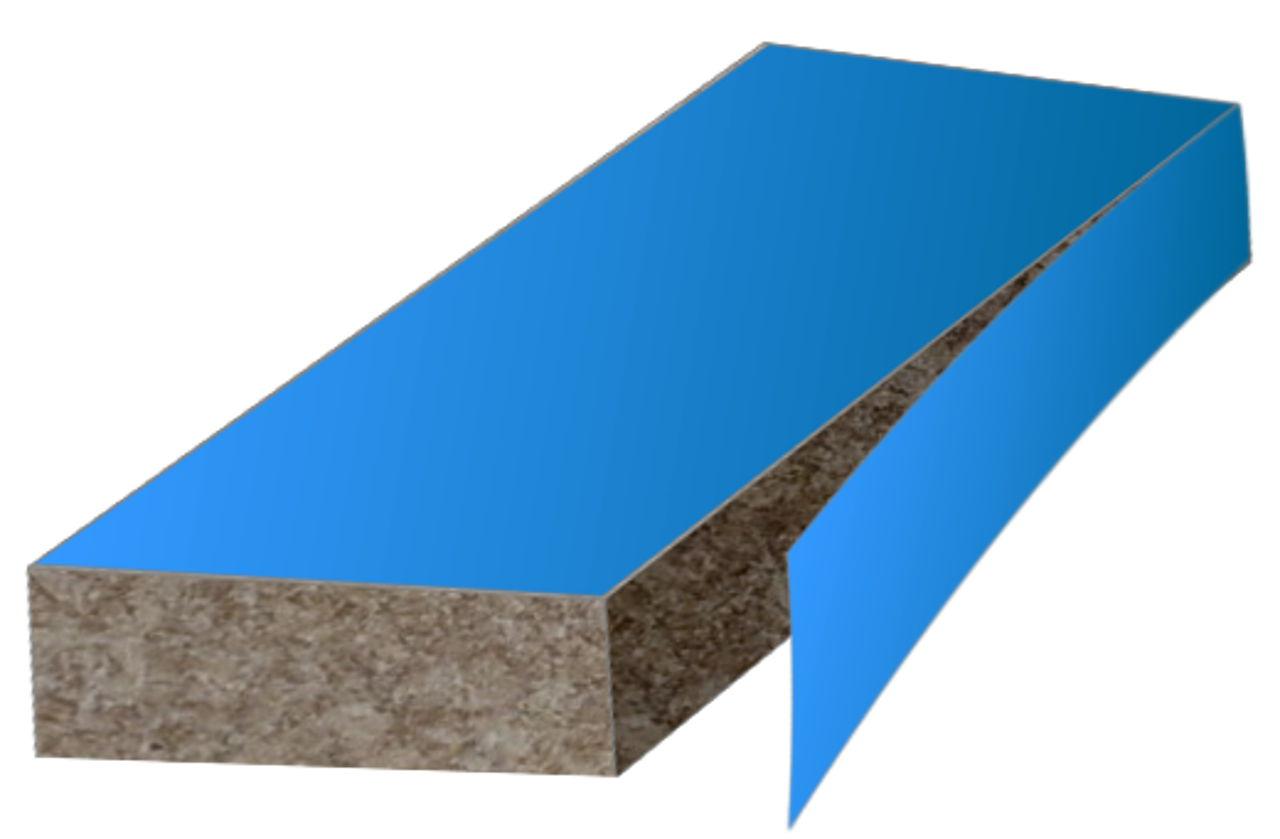

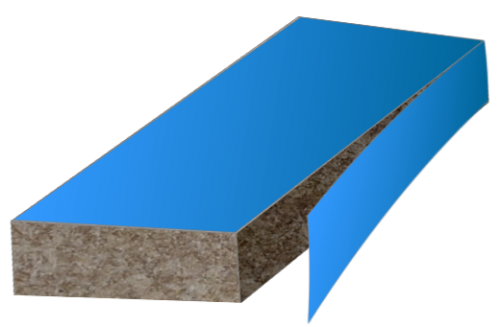

Edgebanding

You see the entry in

The edgebanding machine is an important process when manufacturing furniture and interior construction elements of woodwork materials. If panels coated with foil or veneer are used as starting material, after the cutting and drilling the coating of workpiece narrow edges takes place. For this worksteps are required as described as follows. Working steps with edge gluing oneSuccessively exectued work steps can also be executed in a clamp through a CNC-machining centre which is equipped with the appropriate units. Preparing smal surfaces of the workpiece

Gluing of the edge materialThere are different possibilities to coat a smal surface with edgematerial:

Removing the front and back edge protrusionsEdge material from the roller or in stripes are always put on with a certain protrusion and has to be removed after affixing as follows:

Removal of the top and bottom edge protrusionsEdgematerial from the rollers or in stripes always has to be taller than the workpiece's thickness. This facilitates extra flush levelling the edges with the successively-listed machines over the entire process:

Rounding edgesIn the workpiece edges where the edges meet, sharp-edging overlapping are created. These can be rounded with the successively-listed machines:

Cleaning and polishing of plast material edgesFrom the joint between workpiece and edge adhesive sometimes leaks. With the following gadgeds and machins, this adhesive can be removed:

Chatter marks on the plastic edge, which are created by the blades of the edge milling units can be therefore removed.

The removal of edges with the scraper especially leads to pearlescence which is unwanted. The following possibility for removing pearlescence are:

Cleaning and sanding of veener and solid wood edgesIn preparation of the successive coating, real wood veneers can be sanded with this possibility:

Rear wall groove milling inIf the gluing process of the edges takes place on edgebanding machine, it's better to execute the grooves for the rear of the cabinet with the help of universal milling units. MaschinesIn the commercial production one and double sided edgebanding machines have proved themselves over decades for gluing edges on straight workpieces. Through workpiece return units and robots and the alignment of machine in edge processing lines respectively the workpiece handling can be automatised. Workpieces with bow-shaped edges are being affixed often small handicraft businesses with semi-automatic form part edge gluing machine. In big businesses though CNC-machining centres are more deployed. If the workpieces have profiled edges, they can be coated with the help of Soft- and postforming maschines. If the edges can be glued on construction site, it’s done best with manual edge gluing units. Edge gluing industrialIn the furniture industry the second decade in the third millennium has been cointed by the lot size 1 production. For this reason edgebanding machines which are rather Suite as throughput machines for great serial productions have sky-rocketed in their development. NC-controlled} adjusting mechanisms and multiple rolling magazine fit the machine to the next, different workpiece in seconds. PC-control and barcode scanning units facilitate the involvement in the respective business machining system. |

CNC stacionarne mašine, roboti874

Kantovanje, obrada ivica601

Testere, mašine za rezanje428

Rendisaljke, glodalice189

Glodalice, tenon rezači183

Mašine za bušenje, glodalice129

Prese, mašine za montažu199

Mašine za brušenje323

Mehanizacija, skladištenje, pakovanje178

Površinski premaz141

Proizvodne linije120

Grijanje, sušenje, sjeckanje59

Usisavanje, komprimirani zrak, vakuum119

Tehnologija montaže, radni stolovi11

Strugovi i stružnice35

Alati, tehnologija oštrenja89

Dodatna oprema, ostalo73