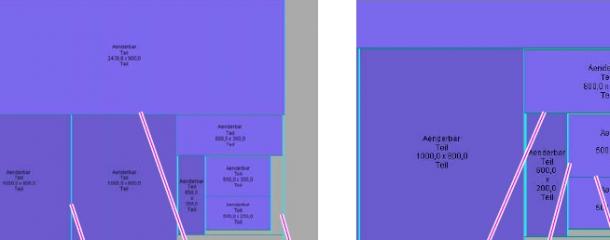

Head cutHead cuts are cuts in lateral direction to a panel and are used in order to achieve a better panel sizing. In order to get a precise and clean edge for referencing, the beamsaw will perform a first cut almost at the end of the raw panel - the edging cut. The head cut is the next step and is done in a 90° angle to the reference edge. For this step, the panel needs to be turned 90°. Many manufacturers offer automatic turning devices (rotary tables), which are integrated in the lifting table at the backside of the machine. The German manufacturer SCHEER integrated a separate head cut aggregat in the machine table in the back of the machines - see head cut device. The Italian manufacturer GABBIANI MACCHINE offers an external third cutting line as a solution for head cuts: External head cut Related terms: |

CNC machining centres, robots894

Edgebanding, edge processing621

Saws, cutting machines437

Planers, 4-sided moulders187

Routers, shapers, tenoners, profilers180

Drilling, mortising machines135

Presses, clamps, joining machines203

Sanding machines325

Mechanisation, storage, packing technology198

Surface coating154

Production lines124

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum136

Assembly, worktables13

Lathes30

Tools, sharpening technology98

Equipment, Other machines110