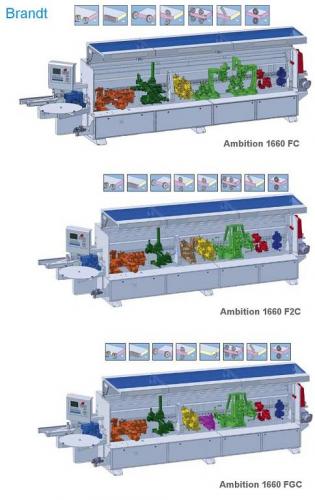

BRANDT AMBITION 1660One-sided edgebander for the processing of straight workpiece edges and for the edgebanding and finishing of different edge materials in lengthwise and cross through-feed. Ambition 1660 FCBasic equipment (2010)

Ambition 1660 F2CBasic equipment (2010)

Ambition 1660 FGCBasic equipment (2010)

Brandt press release for the show LIGNA 2011The Ambition 1660 FGC impresses with its high flexibility, economics and resource efficiency. Motorized adjustment of the upper pressure, program adjustment of the infeed fence and the pressure zone as well as an automatic edge infeed are only a choice of the available options. However, the Ambition 1660 FGC only becomes the Ligna Highlight because of the new gluing unit from BRANDT. Mainly the factors time saving and operation comfort have the primal focus. The short heating time is a maximum of 10 minutes and, already during the preparation of the production unit, a lot of time for the melting of the adhesive is saved. Furthermore, the conversion to different types of adhesives (e.g. PUR or color changes) can be quickly realized since the application unit contains an automatic cleaning and emptying mechanism. Thus, rest times are reduced to a minimum. Even in consideration of resource efficiency and cost saving the Ambition 1660 FGC is perfectly equipped. The optimization of workpiece gaps allows the production of larger workpiece quantities in the same processing time. SimilaritiesTechnical data (2010)

Special equipment (2010)

|  BRANDT AMBITION 1660 BRANDT AMBITION 1660

| |||||||

Images

Product brochures and leaflets (14)

1,69 MBAmbition 1650 - 1660BRANDT, 2009

1,69 MBAmbition 1650 - 1660BRANDT, 2009

0,99 MBAmbition 1650 - 1680BRANDT, 2010

0,99 MBAmbition 1650 - 1680BRANDT, 2010

677,88 KBAmbition 1650 - 1660BRANDT, 2009

677,88 KBAmbition 1650 - 1660BRANDT, 2009

805,84 KBAmbition 1220/1230/1440/ 1650/1860 airTecBRANDT, 2015

805,84 KBAmbition 1220/1230/1440/ 1650/1860 airTecBRANDT, 2015

1,80 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2015

1,80 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2015

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,84 MBAmbition 1650 - 1670 ; KDF 650BRANDT, 2016

1,62 MBAmbition 1650 - 1660BRANDT, 2009

1,62 MBAmbition 1650 - 1660BRANDT, 2009

1,84 MBAMBITION 1600BRANDT, 2016

1,84 MBAMBITION 1600BRANDT, 2016

1,64 MBAMBITION 1650 - 1670 ; KDF 660 editionBRANDT, 2016

1,64 MBAMBITION 1650 - 1670 ; KDF 660 editionBRANDT, 2016

14,94 MBAMBITION 1650 - 1680BRANDT, 2011

14,94 MBAMBITION 1650 - 1680BRANDT, 2011

Types of the series BRANDT AMBITION