Veneer sandingThe feature 'veneer sanding' refers to the adequacy of wide belt sanders for sanding veneered surfaces before the paint job. Problems

Machine equipment

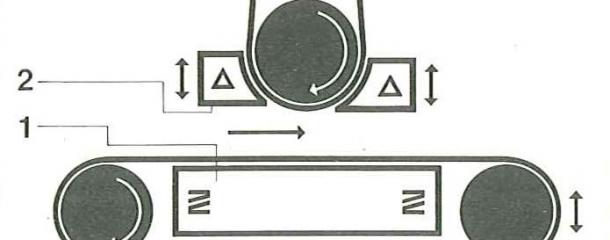

Soft rubber contact rollers are used for the sanding of thick veneer (very rarely, only special machines). Better are somewhat softer sanding pads which achieve the same result and can be used more flexible. Machine set: table resilient, pressure bar fixed. Veneer sheets sanding

|

CNC machining centres, robots894

Edgebanding, edge processing622

Saws, cutting machines436

Planers, 4-sided moulders190

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines324

Mechanisation, storage, packing technology197

Surface coating149

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum139

Assembly, worktables15

Lathes29

Tools, sharpening technology99

Equipment, Other machines124