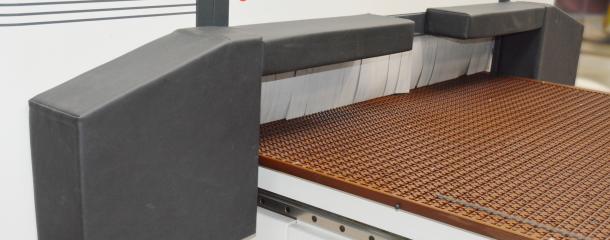

Bumper

You see the entry in

Bumpers are safety devices on CNC-machining centres, which are directly mounted on moving parts (usually the aggregate head). Bumpers must cover all areas of the machine, which in case of a collision can affect a person. Bumpers need to be padded have to cause an immediate stop of the machine movement in case of a collision. The operator must not be overturned. Advantages:

Disadvantages:

Because of the irrefutable advantages of the bumper systems, two-step systems are being used nowadays with high-performing machines, where bumpers with other systems, e.g. light barriers or laser surveillance are combined. If people are outside of both systems, the machine works in full speed. If one person enters the exterior security area the process speed reduces, the machine comes only to a halt by contact with the bumper. At older machines you often find a bumper-like safety system with loosely attached metal plates or rods, which will cause an immediate stop of the machine in case of a collision. These systems are not allowed anymore. See also: SCM Pro-Space, SCM Pro-Speed, HOMAG safeScan |

CNC stacionarne mašine, roboti891

Kantovanje, obrada ivica619

Testere, mašine za rezanje433

Rendisaljke, glodalice186

Glodalice, tenon rezači179

Mašine za bušenje, glodalice133

Prese, mašine za montažu203

Mašine za brušenje323

Mehanizacija, skladištenje, pakovanje194

Površinski premaz152

Proizvodne linije123

Grijanje, sušenje, sjeckanje62

Usisavanje, komprimirani zrak, vakuum136

Tehnologija montaže, radni stolovi13

Strugovi i stružnice30

Alati, tehnologija oštrenja97

Dodatna oprema, ostalo109