Short description

In the late 1990s, HOLZ-HER introduced several CNC-machining centres on the market. The model ECO-MASTER was available as a model of the lower middle class.

Equipment

Initially, there were two different models:

At launch, the machine was available with a table size of 2.536 x 1.283 mm. Furthermore, there was a router head with 4.4 kW, with a standard equipment of a support for horizontal aggregates for holding angular aggregates, a drilling block with 14 vertical drilling spindles and 2 double drilling spindles for horizontal drilling in X and Y as well as a groove saw aggregate (rotatable by 90 degrees).

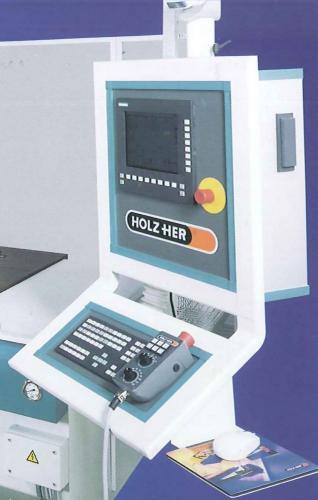

At launch, the machine was still equipped with a slightly modified Siemens control, with WoodStep software, was already known from the models MEGA-CONTROL and MULTIMASTER. However, only a short time later, they switched to using the Sinumerik 810D control, which was equipped with a computer, and the software TwinCAM 32. In cooperation with the company Atemag a range of aggregates for tool changers was developed.

Special equipment

- Horizontal milling aggregate - the tilting device known from the MULTIMASTER is no longer used here

- 2nd vertical milling aggregate

- Additional horizontal double drilling spindle

- Working spindle with higher power

- C-axis

- 3 different tool changers (4-fold pickup tool changer, 6-fold disc tool changer, 12-fold disc changer)

- For the pod and rail table, optionally a digital display was available as help for positioning of vacuum cups

In about 2003, the model series was slightly revised:

- For the first time, a machine suitable for nesting was introduced. It had a matrix table as well as vacuum pump with increased performance.

- For the first time, the newly developed META table was available.

- One could also choose bewteen several drilling blocks with up to 18 vertical drills.

- The tool changers have also been revised. Now available were a 6-fold disc tool changer, 12-fold disc tool changer, 18-fold disc tool changer, 12-fold pickup tool changer, whereas pickup- and disc tool changer could be combined.

- The range of available aggregates was extended.

- The TwinCAM software was revised. Corresponding to up to 8 possible angle stops, now 8 working fields could be worked on.

- For the machine table, a cross laser or a contour laser were optionally available as help for positioning of vacuum cups.

- The standard routing aggregate now had a power of 5.6 instead of 4.4 kW; optionally, moulding aggregates with 6 or 9 kW were available.

- The number of available table sizes (in X) has been extended to 4:

| ECO-MASTER 250 | 2.535 mm |

| ECO-MASTER 340 | 3.435 mm |

| ECO-MASTER 430 | 4.335 mm |

| ECO-MASTER 520 | 5.235 mm |

- In Y, only one table size was available, since here the otherwise identical model UNI-MASTER was used.

At the end of 2003, the design was changed from turquoise to orange. In 2005, the model series ECO-MASTER and UNI-MASTER were discontinued and replaced by the newly developed model PRO-MASTER.